Steel for EVs: Meeting the Challenges of Battery Protection and Lightweighting

943Steel solutions for EV battery cases help automakers ensure safety, lightweighting, and compliance, while suppliers gain stable, cost-effective sourcing.

View detailsSearch the whole station

In demanding industries such as mining, construction, and energy, impact resistant steel plays a vital role in safety and performance. Choosing the right impact resistant steel grades ensures toughness against shocks, wear, and low-temperature failure. By understanding steel impact resistance, engineers can select the most reliable plates and tool steels for bridges, pipelines, and heavy equipment.

Throughout this guide, impact resistant steel is discussed from both structural and tooling perspectives, focusing on how steel impact resistance performs under real industrial conditions.

Impact resistant steel refers to a category of high-strength steels specifically designed to absorb energy during sudden force or deformation without fracturing. These steels typically feature enhanced toughness, ductility, and hardness, making them capable of resisting cracks, dents, and catastrophic failure.

Unlike standard carbon steels, impact resistant steel plates are commonly evaluated using Charpy V-Notch impact testing, which measures the energy absorbed during fracture at specified temperatures. Typical test conditions include –20°C, –40°C, or even –50°C, making impact resistance especially critical for cold-region and safety-sensitive structures.

High impact resistant steel is essential when components are exposed to:

In these scenarios, conventional steel might deform or fracture, leading to expensive downtime or even catastrophic failure.

The impact resistance of steel describes its ability to absorb sudden energy without cracking or fracturing. This property is especially important in dynamic loading environments and low-temperature applications.

Key performance indicators include:

| Property | Description |

|---|---|

| Charpy V-Notch Impact Energy | Measured in Joules (J) at low temperatures like -20°C or -40°C |

| Fracture Toughness | Resistance to crack growth |

| Ductility & Grain Structure | Finer grains improve strength and impact absorption |

High impact resistant steel allows structures such as offshore platforms, lifting beams, and pressure vessels to maintain integrity under shock loading and temperature fluctuations.

Here are several recognized impact resistant steel grades, including both structural and tooling applications:

Several structural steel grades are known for their high impact toughness:

👉 Already working with wear-intensive equipment? Explore our NM400 NM500 series for balanced abrasion and impact resistance.

Impact resistant tool steel is engineered to withstand repeated striking, compression, and shock loading while maintaining dimensional stability. These steels are typically used in dies, molds, and tooling subjected to high mechanical stress.

👉 For specialized tooling under repetitive shock, visit our 5CrW2MoSiV impact tool steel page for technical details.

Tool steels prioritize impact resistance differently from structural steels, focusing on fatigue life and resistance to repeated localized shock rather than large-scale structural loads.

High impact resistant steel plates are designed for the most demanding conditions — from sub-zero pipelines to construction equipment exposed to constant shock.

Common examples include:

These steels are essential for industries where impact resistance of steel directly translates into safety, longevity, and reduced downtime.

| Property | Standard Carbon Steel | Impact Resistant Steel |

| Charpy Impact Energy | Moderate (15–27J) | High (≥ 40J at -20°C or below) |

| Toughness | Moderate | High |

| Crack Propagation | Easier | Slower, controlled |

| Temperature Resistance | Limited in cold climates | Stable at -20°C to -60°C |

| Common Applications | General construction | Tooling, mining, Arctic piping |

In bridge supports, structural beams, and offshore installations, impact resistant steel plates deliver high steel impact resistance, enduring dynamic forces such as wind loads, vibrations, and heavy traffic. By selecting proper impact resistant steel grades, engineers improve safety and extend service life.

For structural components exposed to low temperatures and dynamic loading, impact resistant steel plate for cold weather and high load is commonly specified to ensure long-term safety and toughness.

Pipeline components and pressure vessels must survive both low temperatures and internal pressure surges, especially in arctic environments. High-impact steel is often used for:

Tool steel like 5CrW2MoSiV offers enhanced impact fatigue resistance, making it ideal for forging dies, extrusion tools, and cold heading dies that take thousands of cycles under intense load.

Buckets, blade edges, dump truck liners, and hoppers require steel that resists both impact and abrasion. Here, NM500 plates provide long wear life while preventing sudden cracking.

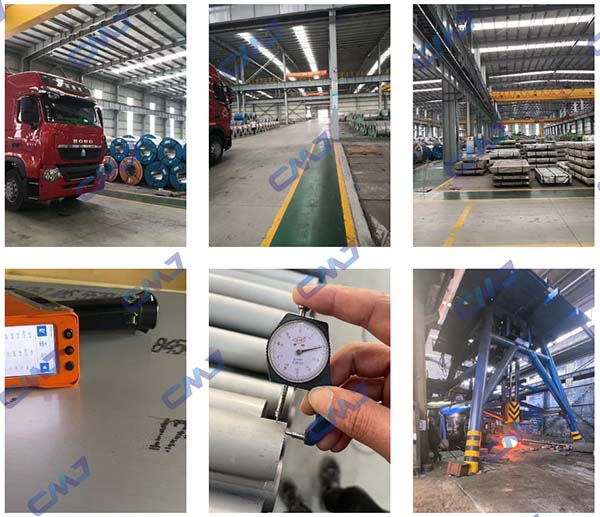

As a global impact steel supplier, CJM Steel Group provides high-toughness structural and tool steel grades sourced from certified manufacturers. We help clients balance mechanical requirements, material costs, and international standards across diverse sectors.

The selection depends on several key factors:

Additional high-impact grades & use cases:

Impact resistant steel is commonly used in mining equipment, bridge supports, tooling dies, and arctic pipelines—applications where durability under sudden or repeated shock is essential.

Impact resistance is often measured by the Charpy V-Notch test, which quantifies the energy a steel sample can absorb before fracture, especially at low temperatures such as -20°C.

Grades like A709, NM500, and tool steels such as S7 or 5CrW2MoSiV are known for their excellent toughness and impact resistance in structural and tooling applications.

Popular impact resistant steel grades include NM500, ASTM A709, A516 Grade 70, and tool steels like S7 and H13.

Tool steels are designed with higher hardness and toughness, making them suitable for molds and dies under repetitive shock. Structural steels prioritize steel impact resistance in large-scale applications such as bridges and pipelines.

CJM Steel Group supplies a wide range of impact resistant steel plates and tool steels, including:

We help clients in mining, mold-making, infrastructure, and pressure vessel manufacturing choose the right impact resistant steel grades for their performance and budget needs.

View our impact resistant plate range →

Contact CJM Steel Group today for a technical consultation or quotation

WhatsApp: +86 181 9190 6640

Email: info@cjmstainlesssteel.com

Selecting the right impact resistant steel isn’t just about strength — it’s about real-world performance under shock, low temperatures, and heavy loads. Working with the right steel grades ensures safety, longevity, and cost-effectiveness.

CJM Steel Group offers a global supply of certified impact resistant steel grades for Arctic structures, heavy machinery, and high-precision tooling, with fast delivery and professional technical support.

Steel solutions for EV battery cases help automakers ensure safety, lightweighting, and compliance, while suppliers gain stable, cost-effective sourcing.

View detailsCalculate steel coil weight online. Supports hot & cold rolled, galvanized, stainless, and aluminum coils. Just enter OD, ID, width to get an quick result.

View detailsCompare S235, S275, and S355 steel grades by strength, composition, and equivalents (ASTM, JIS, GB). Learn which grade best fits your project or trading needs.

View detailsLearn about galvanized steel thicknesses (11, 12, 14, 16, 18, 20, 24 gauge) and sizes. Get expert advice on choosing the right steel sheet for your project.

View details

HelloPlease log in