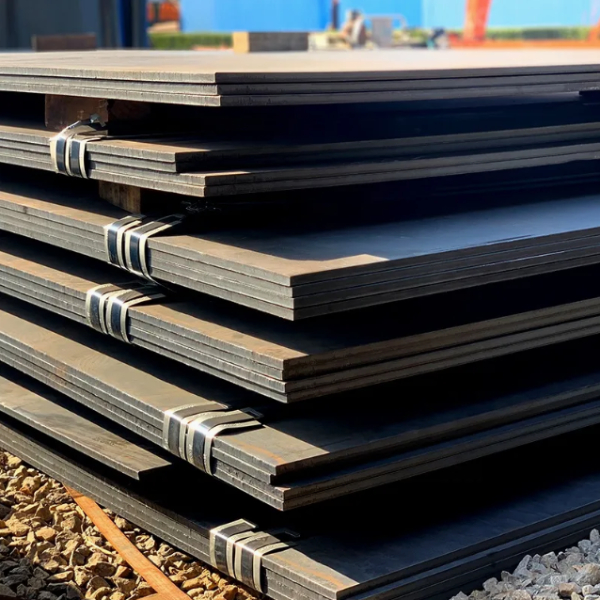

High-Speed Steel for Impact Resistance – 5CrW2MoSiV Tool Steel

Precision. Toughness. Performance.- OriginChina

- Delivery Time≥7 days

- DemandCustomizable

- MOQ 1 Ton

Product Description

Stock Display

Inspection and Packaging

FAQ

Related products

Titanium Grade 2 Plate

- MOQ 1 Ton

- OriginChina

Titanium Grade 7 Plate offers exceptional corrosion resistance, high strength, and excellent weldability, making it ideal for aggressive environments.

Low Carbon Steel Wire Rods

- OriginChina

- Delivery Time≥7 days

Low Carbon Steel Wire Rods are versatile, flexible, and durable, commonly used in construction, manufacturing, and wire products production.

EN 10025-2 / EN 10025-5 Bridge Steel Plate

- OriginChina

- Delivery Time≥7 days

Exporting certified EN 10025-2 and EN 10025-5 bridge steel plates for railway and highway projects. Grades include S355J2, S355J2W, S420J2W, and more.

Hastelloy B-2 Plate

- OriginChina

- Delivery Time≥7 days

Hastelloy C-22 Plate is a corrosion-resistant alloy, ideal for harsh environments, offering excellent resistance to pitting and stress corrosion.

loading…

已经是到最后一篇内容了!

MESSAGE:

CJM Steel Group Ltd.

CJM Steel Group Ltd.