AR500 vs AR550 vs AR600: What’s the Difference?

2117Compare AR500 vs AR550 vs AR600 steel plates. Learn differences in hardness, toughness, price, and applications to choose the right wear-resistant steel.

View detailsSearch the whole station

Q355 steel is one of the most widely used structural steels in China, commonly applied in buildings, bridges, machinery, and welded structures. For international engineers and buyers, the most frequent question is:

“What is Q355 equivalent to in EN, ASTM, and JIS standards?”

This guide provides a clear comparison of Q355 equivalents, chemical composition, mechanical properties, and important engineering notes—making it easier for global buyers to select the right material.

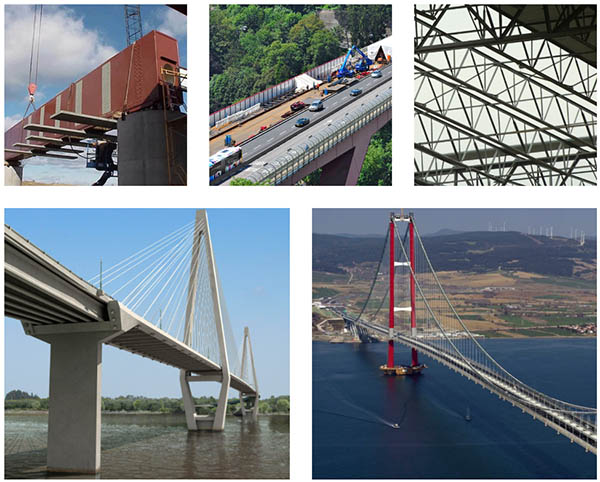

Q355 is a Chinese low-alloy high-strength structural steel defined in GB/T 1591-2018, with a minimum yield strength of 355 MPa. It is commonly used in:

Q355 is available in multiple grades—B, C, D, and E—to support different welding, toughness, and low-temperature requirements. Because of its balanced strength and weldability, Q355 material has become a major option for global engineering companies.

| Property | Q355 | S355 |

|---|---|---|

| Minimum Yield Strength | ≥355 MPa | ≥355 MPa |

| Tensile Strength | 470–630 MPa | 470–630 MPa |

| Elongation | Similar | Similar |

| Grade | Temperature | Requirement |

|---|---|---|

| Q355B | +20°C | ≥27 J |

| Q355C | 0°C | ≥27 J |

| Q355D | −20°C | ≥27 J |

| Q355E | −40°C | ≥27 J |

| S355JR | +20°C | ≥27 J |

| S355J0 | 0°C | ≥27 J |

| S355J2 | −20°C | ≥27 J |

| S355NL | −50°C | Higher notch toughness |

Q355 is generally equivalent to S355 in both strength and performance.

*For most structural applications, Q355 can be considered a functional equivalent to S355 when the correct grade is selected and approved by the project’s design authority.

For a broader understanding of S-series structural steels, you may also read our detailed comparison guide: S235/S275/S355 Structural Steel Comparison.

Below is the commonly accepted international equivalence:

| Chinese Standard | Equivalent Standard | Grade |

|---|---|---|

| GB/T 1591 | EN 10025-2 | S355JR / S355JO / S355J2 |

| GB/T 1591 | ASTM A572 | Grade 50 (based on yield strength) |

| GB/T 1591 | JIS G3106 | SS490* |

*Note: SS490 comparison is based mainly on tensile properties; confirm yield strength, impact toughness, and specification requirements before substitution.

Below is the chemical composition of Q355 according to GB/T 1591-2018 (for thickness ≤ 16 mm, maximum values unless noted):

| Element | Q355B | Q355C | Q355D | Q355E |

| C | ≤0.24% | ≤0.22% | ≤0.20% | ≤0.18% |

| Si | ≤0.55% | ≤0.55% | ≤0.55% | ≤0.55% |

| Mn | ≤1.60% | ≤1.60% | ≤1.60% | ≤1.60% |

| P | ≤0.035% | ≤0.035% | ≤0.030% | ≤0.025% |

| S | ≤0.035% | ≤0.035% | ≤0.030% | ≤0.020% |

| Nb+V+Ti | ≤0.12% | ≤0.12% | ≤0.12% | ≤0.12% |

*Values follow GB/T 1591-2018

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Impact Temperature |

| Q355B | ≥355 | 470–630 | ≥22 | 20°C |

| Q355C | ≥355 | 470–630 | ≥22 | 0°C |

| Q355D | ≥355 | 470–630 | ≥22 | −20°C |

| Q355E | ≥355 | 470–630 | ≥22 | −40°C |

*The above are the minimum requirements per GB/T 1591-2018 for rolled sections and plates. Q355E provides enhanced low-temperature toughness, suitable for cold regions, offshore structures, and energy projects.

| Application Scenario | Recommended Grade |

|---|---|

| General construction | Q355B |

| Welding-focused structures | Q355C |

| Outdoor / cold regions | Q355D |

| Extremely low temperature | Q355E |

Key Differences

Yes—Q355 steel can replace S355 and A572 Gr.50 in many applications such as:

However, the substitution is not automatic. It requires:

To summarize:

Now that the equivalence is clear, the next step is selecting the right product form.

To ensure structural safety, selecting the appropriate Q355 grade is critical. Ready to proceed? Choose the product that matches your project’s needs:

Compare AR500 vs AR550 vs AR600 steel plates. Learn differences in hardness, toughness, price, and applications to choose the right wear-resistant steel.

View detailsCompare S355JR, S355J2, and S355NL steel grades under EN 10025. See yield strength, toughness, equivalents, and applications for construction & offshore use.

View detailsCompare ASTM A709 steel plate grades 50, 50W, and HPS 70W for bridge construction. Learn strength, weathering performance, and typical applications.

View detailsCarbon steel wire is a widely used material in various industries due to its strength, durability, and cost-effectiveness. It is commonly found in applications ranging from automotive to construction, offering an excellent balance of performance a...

View details

HelloPlease log in