Structural Steel Sourcing Guide: Types, Grades, and Global Standards

1118Discover structural steel grades, types, and global standards. Compare A36, S235JR, S355, A572, A588 and more. Practical sourcing tips for global buyers.

View detailsSearch the whole station

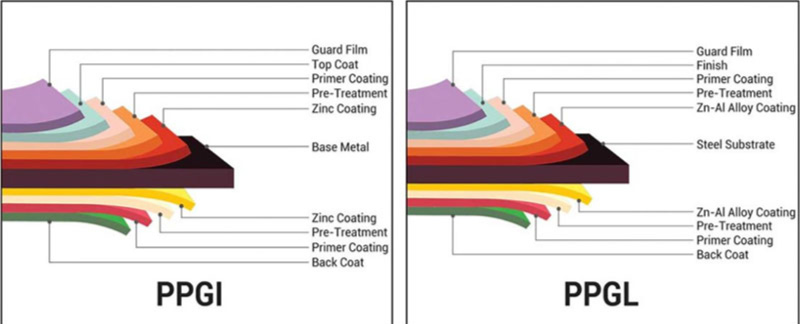

When sourcing prepainted steel products, one of the most common questions buyers ask is: PPGI vs PPGL – which is better? Both PPGI and PPGL steel sheets belong to the prepainted steel family and are widely used in roofing, wall panels, and appliances. However, they differ significantly in coating composition, corrosion resistance, and application suitability.

Understanding the ppgi and ppgl difference helps buyers reduce costs, improve durability, and choose the right material for specific projects.

PPGI steel sheet is produced by applying a color coating on hot-dip galvanized steel. The zinc coating provides corrosion resistance, while the paint layer enhances surface finish and durability.

If color design, pattern variety, and aesthetic impact are priorities, PPGI is often the better option.

Explore our range of patterned and printed PPGI sheets for decorative building projects.

PPGL steel sheet is made from aluminum-zinc alloy coated steel (55% Al, 43.5% Zn, 1.5% Si) with a color coating on top. This combination provides superior durability, especially in aggressive environments.

For industrial and coastal use, ppgl sheets are often chosen over PPGI due to their enhanced lifespan.

For buyers comparing PPGI vs PPGL steel sheets, the following table highlights the key differences in coating, performance, and typical applications:

| Feature | PPGI | PPGL |

| Base Metal | Galvanized Steel (Zinc Coated) | Galvalume Steel (Al-Zn Coated) |

| Corrosion Resistance | Good | Excellent |

| Heat Resistance | Standard | Superior |

| Paint Adhesion | Excellent | Good |

| Surface Texture | Smooth | Smooth with metallic sheen |

| Typical Use | Decorative panels, roofing, appliances | Industrial roofing, coastal buildings |

In practical use, ppgi vs ppgl sheets come down to priorities:

Not sure which one fits your project better?

Tell us your project location, exposure environment, and expected service life, and we’ll help you choose between PPGI or PPGL with a suitable coating and thickness.

| Item | PPGI | PPGL |

| Initial Material Cost | Lower | Slightly higher |

| Maintenance Frequency | Medium | Low |

| Expected Lifespan (Typical Outdoor Use) | 5–10 years | 10–20 years+ |

| Total Cost Over Use Cycle | Balanced | More economical for long-term projects |

Choosing based on price alone can be misleading.

If you’re comparing PPGI vs PPGL for roofing or long-term outdoor use, we can help you evaluate total cost over service life and recommend the right option for your project.

Roofing is one of the most common scenarios where buyers compare PPGI vs PPGL sheet. The performance difference becomes more noticeable when climate and service life are considered.

When comparing PPGI vs PPGL for roofing, buyers should consider local climate, coating system (PE, SMP, or PVDF), sheet thickness, and the expected lifespan of the building. In many export markets, PPGL roofing sheets are increasingly specified for warehouses and logistics centers due to longer repainting intervals.

Check our blog about it to get more idea – How to Choose the Right Steel Sheet for Your Roof.

When comparing PPGI vs PPGL steel sheets, the right choice depends less on the product name and more on the project environment, expected service life, and budget priorities.

Understanding these factors helps buyers make a practical decision when choosing between PPGI and PPGL sheets.

The choice between ppgi vs ppgl depends on environment, budget, and application goals. PPGI is cost-effective, decorative, and versatile, while PPGL offers superior corrosion and heat resistance for demanding outdoor use. CJM supply PPGI & PPGL coils, sheets, and customized roofing profiles with stable stock, international packing standards, and fast delivery.

Email: info@cjmstainlesssteel.com

WhatsApp: +86 18191906640

If you’re still comparing PPGI vs PPGL for your project, feel free to contact us with your application and location. We’ll help you make a practical, cost-effective choice.

Discover structural steel grades, types, and global standards. Compare A36, S235JR, S355, A572, A588 and more. Practical sourcing tips for global buyers.

View detailsLearn about galvanized steel thicknesses (11, 12, 14, 16, 18, 20, 24 gauge) and sizes. Get expert advice on choosing the right steel sheet for your project.

View detailsChoosing the right steel grade is a critical decision in shipbuilding and offshore engineering. Among the commonly used grades under the ASTM A131 standard, AH32, AH36, and AH40 steel plates stand out for their balance of strength, toughness, ...

View detailsExplore MnCrWv tool steel along with Cr12, Cr12MoV (D2), 9CrSi, GCr15 and T10A for stamping and die manufacturing. Covers performance, application and sourcing.

View details

HelloPlease log in