U Channel Steel Guide for Distributors & Construction Companies

3085Comprehensive guide on U Channel Steel: standard sizes, materials, price factors, and applications for distributors & construction projects worldwide.

View detailsSearch the whole station

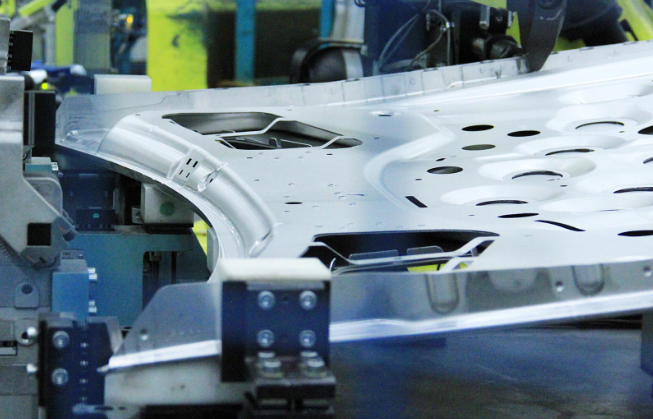

Automotive body panels—including doors, hoods, fenders, and trunk lids—play a critical role in vehicle appearance, durability, and long-term corrosion protection. Selecting the right automotive steel sheet for these exterior components is therefore a key consideration in vehicle manufacturing.

Across different vehicle parts, automotive steel sheet is supplied in various forms and grades depending on structural, corrosion, and forming requirements. Among these options, galvanized automotive steel sheet has become the preferred choice for exterior car body panels due to its balanced performance and cost efficiency.

Automotive body panels must meet several functional and production requirements:

These requirements explain why not all steel materials qualify as automotive panel steel.

Galvanized steel for the automotive industry is widely used for exterior body panels because it offers a unique balance of performance and cost.

Main types used in car body panels include:

Over 70% of exterior car body panels worldwide are manufactured using galvanized automotive steel sheets.

For a detailed explanation of base materials—such as low carbon steel, HSLA, and dual-phase steel—used in vehicle manufacturing, refer to our Automotive Steel Grades Guide.

Carbon steel sheet in automotive applications remains common for both OEM and repair markets due to its cost advantage. While other materials are also used in the automotive industry, they come with certain limitations:

| Material | Pros | Cons |

|---|---|---|

| Galvanized Steel Sheet | Cost-effective, corrosion-resistant, good formability | Slightly heavier than aluminum |

| Aluminum Alloys | Lightweight | Expensive, harder to process |

| Stainless Steel | Durable, rust-proof | Costly, limited formability |

| Advanced High-Strength Steel (AHSS) | High strength, lightweight | Mainly for structural parts, not exterior panels |

This comparison explains why metal sheet for car body applications most commonly refers to galvanized steel in passenger vehicles.

The global automotive industry is moving toward lighter, safer, and more sustainable vehicles. This is driving innovation in steel manufacturing, including:

Automotive steel sheet will continue to balance performance, cost, and regulatory compliance in the coming years.

For car body panels, no material matches the combination of durability, corrosion resistance, formability, and cost-effectiveness offered by galvanized automotive steel sheet.

To explore product options tailored for automotive applications, visit ourAutomotive Steel Plate Collection or Contact Our Team for product specification.

Comprehensive guide on U Channel Steel: standard sizes, materials, price factors, and applications for distributors & construction projects worldwide.

View detailsUnderstand the key differences between carbon steel and alloy steel. Compare strength, cost, and best use cases. Expert buying tips from CJM.

View detailsDiscover 4140 steel overview: key specifications, broad applications in automotive, machinery, and energy industries and main features for buyers and engineers.

View detailsWhy shooting target manufacturers prefer AR500 steel plate for durability and cost efficiency? Learn how target steel properties make it the standard choice.

View details

HelloPlease log in