U Channel Steel Guide for Distributors & Construction Companies

3086Comprehensive guide on U Channel Steel: standard sizes, materials, price factors, and applications for distributors & construction projects worldwide.

View detailsSearch the whole station

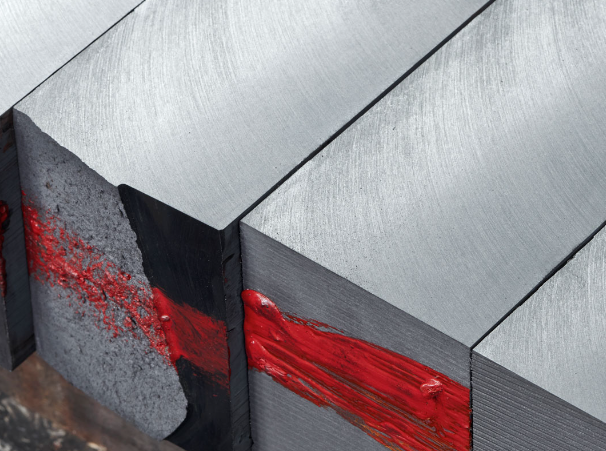

When choosing tool steel for knives, dies, or precision tools, O1 tool steel and A2 tool steel are among the most popular options. Both offer high wear resistance and toughness, but they differ significantly in terms of heat treatment, hardness, and performance.

Whether you’re a knife manufacturer, tool maker, or distributor, choosing between O1 and A2 tool steel for sale affects not only blade performance but also cost efficiency and supply stability. This guide compares both grades to help you choose the best steel for production or resale.

In this guide, we compare O1 vs A2 steel in depth — helping you decide which is better for your application.

O1 tool steel is a high-carbon, oil-hardening tool steel known for its excellent edge retention and dimensional stability. It is widely used in:

👉 Learn more about other cold work tool steel options in our article: Cold Work Tool Steel Grades: Properties & Applications

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.90 – 1.00 |

| Chromium (Cr) | 0.40 – 0.60 |

| Tungsten (W) | 0.40 – 0.60 |

| Manganese (Mn) | 1.00 – 1.40 |

| Silicon (Si) | ≤ 0.50 |

| Vanadium (V) | ≤ 0.30 |

👉 For knifemakers, heat treating O1 tool steel produces blades that hold an edge longer than many other carbon steels.

Advantages:

Disadvantages:

A2 tool steel is an air-hardening, medium-alloy cold work steel offering a balance of wear resistance and toughness. It is commonly used in:

👉 Interested in impact-resistant tool steel? Check out our 5CrW2MoSiV Impact-Resistant Tool Steel designed for high-load applications.

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.95 – 1.05 |

| Chromium (Cr) | 4.75 – 5.50 |

| Molybdenum (Mo) | 0.90 – 1.40 |

| Manganese (Mn) | ≤ 1.00 |

| Vanadium (V) | 0.15 – 0.30 |

The higher chromium and molybdenum content make A2 steel more resistant to wear and chipping than O1 steel.

Because it is air hardening, heat treating A2 tool steel produces less distortion, making it ideal for precision tooling.

👉 For a detailed breakdown of thermal processing and material strength, visit our blog: 4Cr3Mo3SiV Hot Work Tool Steel Properties

| Property | Value |

|---|---|

| A2 tool steel hardness (after tempering) | 58–63 HRC |

| Hardness before heat treat | ~20 HRC |

| Yield Strength | ~2000 MPa |

| Toughness | High (better than O1) |

| Wear Resistance | Moderate to high |

| Corrosion Resistance | Slightly better than O1 |

| Feature | O1 Tool Steel | A2 Tool Steel |

|---|---|---|

| Hardening Method | Oil quench | Air hardening |

| Final Hardness | 57–62 HRC | 58–63 HRC |

| Machinability | Easier | Moderate |

| Distortion on Heat Treat | Moderate | Low |

| Wear Resistance | High | Moderate-High |

| Toughness | Moderate | High |

| Ideal for Knives? | ✅ Yes | ✅ Yes |

| Ideal for Tooling? | ✅ Yes | ✅ Yes |

| Best For | Custom knives, dies | Precision dies, larger tools |

In global markets, O1 tool steel is generally more affordable and widely stocked due to its simpler oil-hardening process.

A2 tool steel costs slightly more but offers better performance for large or high-precision tools.

CJM provides both O1 and A2 tool steel for sale, available in plates, sheets, and round bars. Both grades are available from our tool steel stock, complete with mill certificates and global delivery support. We offer cut-to-size service, export packaging, and bulk pricing for international customers.

Both o1 knife steel and A2 knife steel are viable, depending on the knife’s purpose.

The debate of O1 vs A2 steel doesn’t have a single winner—it depends on application.

A2 steel is better for heavy-duty knives and tooling that require toughness.

O1 steel is ideal for precision knives and cutting tools where sharpness matters most.

Looking for a supplier? CJM supplies O1 and A2 tool steel for knives, dies, and industrial tooling — available for sale in plates, bars, and sheets. Contact us for bulk orders, OEM service, and custom-size cutting with fast international delivery.

Email: info@cjmstainlesssteel.com

WhatsApp: +86 181 9190 6640

Comprehensive guide on U Channel Steel: standard sizes, materials, price factors, and applications for distributors & construction projects worldwide.

View detailsUnderstand the technical and regulatory differences between structural and pressure vessel steel plates. Compare grades, properties, and applications in one guide.

View detailsDiscover which steel plate grades suit offshore oil & gas and shipbuilding. Compare EH36, AH36, API 2H, and S420G2 for corrosion resistance, strength, and certification.

View detailsUnderstand the key differences between carbon steel and alloy steel. Compare strength, cost, and best use cases. Expert buying tips from CJM.

View details

HelloPlease log in