What are carbon steel profiles?

1337Learn what carbon steel profiles are, their main types (I-beam, channel, angle), properties, and industrial uses. Find reliable carbon steel profiles suppliers.

View detailsSearch the whole station

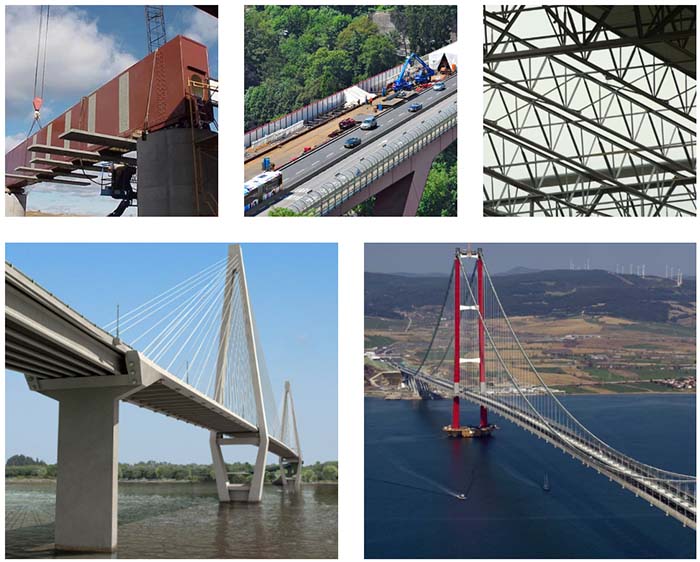

In modern infrastructure projects—especially bridges and overpasses—ASTM A709 steel plate has become a preferred material choice due to its strength, durability, and resistance to corrosion. Among its grades, ASTM A709 Grade 50W weathering steel and HPS 70W are the most popular for modern bridge construction due to their combination of corrosion resistance, mechanical strength, and long-term durability.

This article focuses on how to choose the right ASTM A709 grade based on structural performance and weathering requirements, helping engineers and project teams make informed material decisions for bridge applications.

ASTM A709 is a structural steel specification developed specifically for bridge construction. It covers a range of carbon and high-strength low-alloy (HSLA) steels intended for critical load-bearing members.

Key performance requirements addressed by ASTM A709 include:

Typical grade characteristics include:

Understanding these differences is essential before selecting a material for a specific bridge environment.

During bridge design and fabrication, ASTM A709 steel may appear in different product forms depending on structural function and fabrication methods.

These forms reflect design and fabrication choices, not performance differences within the ASTM A709 specification itself.

For detailed dimensions, thickness ranges, and available grades used in bridge fabrication, you can refer to our ASTM A709 bridge steel plate product page.

Grade 50W forms a stable protective oxide layer (patina) when exposed to suitable environments, reducing the need for painting and long-term maintenance. It is commonly specified for exposed bridge structures where lifecycle cost control is a priority.

HPS 70W enables lighter structural designs while maintaining excellent fracture resistance, even in colder climates.

ASTM A709 Grade 50W weathering steel is particularly suitable for unpainted, exposed bridge structures. Its protective patina minimizes further corrosion under appropriate environmental conditions.

It is often specified for:

In bridge design, Grade 50W may be detailed into angles or rounds for exposed elements where both structural performance and appearance are considered.

Below are the key mechanical properties of ASTM A709 Grade 50W weathering steel compared with HPS 70W:

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Charpy V-Notch Toughness |

| 50W | 345 | 485–620 | ≥ 18 | Good at ambient temps |

| HPS 70W | 485 | 585–760 | ≥ 19 | Excellent at low temps |

From a selection perspective:

When selecting an ASTM A709 grade, engineers and project teams usually evaluate:

These factors often determine whether standard, weathering, or high-performance steel is the most appropriate choice.

Here’s a brief selection guide:

ASTM A709 steel provides a versatile and performance-driven solution for modern bridge construction. Selecting the appropriate grade—whether Grade 50, Grade 50W weathering steel, or HPS 70W—depends on structural demands, environmental exposure, and long-term performance objectives.

A clear understanding of these differences allows engineers and project teams to make technically sound and cost-effective material choices.

For specifications, grade availability, and application details, you can view our A709 rolled plate supplier product page.

Learn what carbon steel profiles are, their main types (I-beam, channel, angle), properties, and industrial uses. Find reliable carbon steel profiles suppliers.

View detailsComprehensive guide about ASTM A514 steel plate: strength, hardness, welding, machinability, chemical composition, and equivalent grades for your projects.

View detailsComplete Q355 steel equivalent guide covering EN S355, ASTM A572 Gr.50, chemical composition, mechanical properties, and grade selection (B/C/D/E).

View detailsCarbon steel coils are widely utilized in a range of industries due to their strength, versatility, and affordability.

View details

HelloPlease log in