Bridge Steel Plate & Coil for Durable Bridge Construction

High strength bridge steel plate- OriginChina

- Delivery Time≥7 days

- DemandCustomizable

- MOQ 1 Ton

Superior Quality Bridge Steel Plate & Coil for Global Infrastructure Projects

Our Bridge Steel Plates and Bridge Steel Coils are specially designed for use in the construction of durable and reliable railway and highway bridges. With a focus on strength, weldability, and corrosion resistance, our products meet international standards, including GB, ASTM, and EN, and are ideal for various bridge structures, including decks, supports, and foundations.

Product Standards:

EN 10025

GB/T 714

ASTM A709 Gr.36 / Gr.50

To help you better understand the quality and performance of our bridge steel products, we have prepared detailed tables outlining their chemical composition and mechanical properties. These specifications are essential for evaluating strength, weldability, and overall suitability for structural and bridge applications.

Steel grade and dimension

| Steel grade | Dimension (mm) | Standard | Delivery condition | ||

| Thickness | width | Length | |||

| Q345qC~E Q370qC~E | 6~150 6~120 | 1050~4050 | 5000~23000 | GB/T 714 | AR、N、TMCP |

| Q345qNHD~F Q370qNHD~F Q420qNHD~F | 6~100 6~100 6~80 | AR、TMCP、TMCP+T | |||

| Q500qNHD~F | 6~80 | TMCP+T、QT | |||

| Q420qD~F Q460qD~F Q500qD~F | 6~90 6~80 6~80 | TMCP TMCP+T | |||

| Q690qD~F | 10~50 | TMCP+T、QT | |||

| A709 Gr.36/ Gr.50 A709-50F-2/50T-2 A709 Gr.50WA/WB | 6~150 6~150 6~100 | Q/SGZGS 0335.3 ASTM A709 | AR、CR、TMCP、N | ||

Chemical Composition

Table 1 Requirements for P、S、B、H composition of various grades

| Quality Grade | Chemical Composition, % | |||

| P | S | Ba,b | Ha | |

| ≤ | ||||

| C | 0.030 | 0.025 | 0.0005 | 0.0002 |

| D | 0.025 | 0.020 | ||

| E | 0.020 | 0.010 | ||

| F | 0.015 | 0.006 | ||

| Note: a. When the supplier can ensure the residual elements B and H in the steel grade, chemical analysis may be omitted. b. For quenched and tempered steels with intentionally added boron (B), this limitation does not apply; analysis must be conducted and included in the quality certificate. c. For steel grades Q420 and above, the sulfur (S) content shall not exceed 0.015%. | ||||

Table 2 Chemical Composition of Hot Rolled or Normalized Steel

| Steel grade | Quality Grade | Chemical Composition(%) | ||||||||||

| C | Si | Mn | Nba | Va | Tia | Alsa,b | Cr | Ni | Cu | N | ||

| ≤ | ≤ | |||||||||||

| Q345q | C D E | 0.18 | 0.55 | 0.90~1.60 | 0.005~0.060 | 0.010~0.080 | 0.006~0.030 | 0.010~0.045 | 0.30 | 0.30 | 0.30 | 0.0080 |

| Q370q | 1.00~1.60 | |||||||||||

| Note: a. For steel grades of type A, aluminum (Al), niobium (Nb), vanadium (V), and titanium (Ti) may be added individually or in combination. When added individually, the content shall meet the specified range in the table. When added in combination, at least one alloying element must meet the lower limit specified in the table, and the total content of Nb + V + Ti shall not exceed 0.22%. b. When calculating based on total aluminum (Alt) content, the Alt shall be within the range of 0.015% to 0.050%. | ||||||||||||

Table 3 Chemical Composition of Thermomechanical Rolled Steel

| Grade | Quality Grade | Chemical Composition(%) | |||||||||||

| C | Si | Mna | Nbb | Vb | Tib | Alsb,c | Cr | Ni | Cu | Mo | N | ||

| ≤ | ≤ | ||||||||||||

| Q345q | C D E | 0.14 | 0.55 | 0.90~1.60 | 0.010~0.090 | 0.010~0.080 | 0.006~0.030 | 0.010~0.045 | 0.80 | 0.30 | 0.30 | – | 0.0080 |

| Q370q | D E | 1.00~1.60 | |||||||||||

| Q420q | D E F | 0.17 | 1.00~1.70 | 0.50 | 0.30 | 0.20 | |||||||

| Q460q | 0.25 | ||||||||||||

| Q500q | 0.80 | 0.70 | 0.30 | ||||||||||

| Note: a. Upon agreement between the supplier and the purchaser, the manganese (Mn) content may be increased up to a maximum of 2.00%. b. Aluminum (Al), niobium (Nb), vanadium (V), and titanium (Ti) may be added individually or in combination. When added individually, their contents shall comply with the specified values in the table. When added in combination, at least one alloying element must meet the minimum specified limit, and the total content of Nb + V + Ti shall not exceed 0.22%. c. When calculated based on total aluminum (Alt) content, the Alt shall range from 0.015% to 0.050%. | |||||||||||||

Table 4 Chemical composition of quenched and tempered steel

| Grade | Quality Grade | Chemical Composition(%) | |||||||||||

| C | Si | Mn | Nba | Va | Tia | Alsa,b | Cr | Ni | Cu | Mo | N | ||

| ≤ | |||||||||||||

| Q500q | D E F | 0.11 | 0.55 | 0.80~1.70 | 0.005~0.060 | 0.010~0.080 | 0.006~0.030 | 0.010~0.045 | ≤ 0.80 | ≤ 0.70 | ≤ 0.30 | ≤ 0.30 | ≤0.0080 |

| Q550q | 0.12 | ||||||||||||

| Q620q | 0.14 | 0.005~0.090 | 0.40~0.80 | 0.25~1.00 | 0.15~ 0.55 | 0.20~0.50 | |||||||

| Q690q | 0.15 | 0.40~1.00 | 0.40~1.20 | 0.20~0.60 | |||||||||

| Note: Boron (B) may be added in the range of 0.005% to 0.030%. | |||||||||||||

| Note: a. Aluminum (Al), niobium (Nb), vanadium (V), and titanium (Ti) may be added individually or in combination. When added individually, the content shall comply with the specified values in the table. When added in combination, at least one alloying element must meet the minimum specified limit, and the total content of Nb + V + Ti shall not exceed 0.22%. b. When calculated based on total aluminum (Alt) content, the Alt shall range from 0.015% to 0.050%. | |||||||||||||

Table 5 Chemical Composition of Atmospheric Corrosion Resistant Steel

| Grade | Quality Grade | Chemical Composition a(%) | |||||||||||

| C | Si | Mn | Nb | V | Ti | Cr | Ni | Cu | Mo | N | Alsb | ||

| ≤ | |||||||||||||

| Q345qNH | D E F | ≤ 0.11 | 0.15~ 0.50 | 1.10~ 1.50 | 0.010~ 0.100 | 0.010~ 0.100 | 0.006~ 0.030 | 0.40~ 0.70 | 0.30~ 0.40 | 0.25~ 0.50 | 0.10 | 0.0080 | 0.015~0.050 |

| Q370qNH | 0.15 | ||||||||||||

| Q420qNH | 0.20 | ||||||||||||

| Q345qNH | |||||||||||||

| Q460qNH | |||||||||||||

| Q500qNH | 0.45~ 0.70 | 0.30~ 0.45 | 0.25~ 0.55 | 0.25 | |||||||||

| Q550qNH | |||||||||||||

| Note: a. Niobium (Nb), vanadium (V), titanium (Ti), and aluminum (Al) may be added individually or in combination. When added in combination, at least one alloying element must meet the minimum specified limit, and the total content of Nb + V + Ti shall not exceed 0.22%. b. When calculated based on total aluminum (Alt) content, the Alt shall range from 0.020% to 0.055%. | |||||||||||||

Ceq

| Delivery Condition | Steel Grade | Carbon Equivalent (CEV), % | ||

| Thickness,mm | ||||

| ≤ 50 | > 50 ~ 100 | > 100 ~ 150 | ||

| Hot Rolled or Normalized | Q345q | ≤ 0.43 | ≤ 0.45 | Mutual Agreement |

| Q370q | ≤ 0.44 | ≤ 0.46 | ||

| Thermomechanical Rolling | Q345q | ≤ 0.38 | ≤ 0.40 | – |

| Q370q | ≤ 0.38 | ≤ 0.40 | ||

| Quenched and Tempered (Q&T) | Q500q | ≤ 0.50 | ≤ 0.55 | Mutual Agreement |

| Q550q | ≤ 0.52 | ≤ 0.57 | ||

| Q620q | ≤ 0.55 | ≤ 0.60 | ||

| Q690q | ≤ 0.60 | ≤ 0.65 | ||

| Note: The calculation formula for carbon equivalent: Ceq(%) = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15. The carbon equivalent for weather-resistant steel may be specified by mutual agreement between the supplier and the purchaser, based on the values in this table. | ||||

Pcm

| Steel Grade | Pcm, % | Steel Grade | Pcm, % |

| ≤ | ≤ | ||

| Q345q | 0.20 | Q500q | 0.25 |

| Q370q | 0.20 | Q550q | 0.25 |

| Q420q | 0.22 | Q620q | 0.25 |

| Q460q | 0.23 | Q690q | 0.25 |

| Note: For all grades of steel, except weather-resistant steel, when the carbon content is less than or equal to 0.12%, the weldability of the steel is evaluated using the weld crack sensitivity factor (Pcm) instead of the carbon equivalent. The formula for Pcm is as follows: Pcm = C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/10 + 5B. | |||

Mechanical Properties

| Steel Grade | Tensile Test (a, b) | Impact Test (c) | ||||||

| Lower Yield Strength (ReL / MPa) | Ultimate Tensile Strength (Rm / MPa) | Elongation after Fracture (A / %) | Test Temperature (°C) | Impact Absorbed Energy (KV2 / J) | ||||

| Thickness (mm) | ||||||||

| ≥ 3 ≤ 50 | > 50 ≤ 100 | > 100 ≤ 150 | ||||||

| ≥ | ≥ | |||||||

| Q345q | C | 345 | 335 | 305 | 490 | 20 | 0 | 120 |

| D | -20 | |||||||

| E | -40 | |||||||

| Q370q | C | 370 | 360 | – | 510 | 20 | 0 | 120 |

| D | -20 | |||||||

| E | -40 | |||||||

| Q420q | D | 420 | 410 | – | 540 | 19 | -20 | 120 |

| E | -40 | |||||||

| F | -60 | 47 | ||||||

| Q460q | D | 460 | 450 | – | 570 | 19 | -20 | 120 |

| E | -40 | |||||||

| F | -60 | 47 | ||||||

| Q500q | D | 500 | 480 | – | 630 | 18 | -20 | 120 |

| E | -40 | |||||||

| F | -60 | 47 | ||||||

| Q550q | D | 550 | 530 | – | 660 | 16 | -20 | 120 |

| E | -40 | |||||||

| F | -60 | 47 | ||||||

| Q4620q | D | 620 | 580 | – | 720 | 15 | -20 | 120 |

| E | -40 | |||||||

| F | -60 | 47 | ||||||

| Q690q | D | 690 | 650 | – | 770 | 14 | -20 | 69 |

| E | -40 | |||||||

| F | -60 | |||||||

| Note: a. When the yield point is not clearly defined, the RP0.2 can be measured to replace the lower yield strength. b. For the tensile test, a transverse specimen shall be used. c. For the impact test, a longitudinal specimen shall be used. | ||||||||

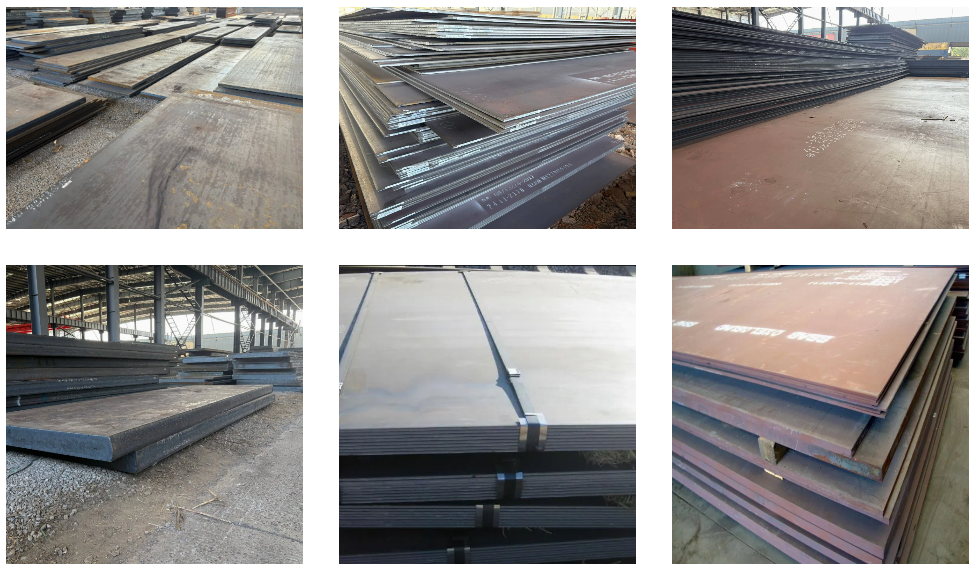

Key Features of Our Bridge Steel Plate & Coil

- Weather-resistant Steel: Our Bridge Steel Plates feature superior resistance to atmospheric corrosion, making them perfect for bridges exposed to harsh environmental conditions.

- High Strength: With steel grades capable of reaching a tensile strength of up to 500 MPa, our steel plates ensure long-term durability under heavy load-bearing conditions.

- Versatile Delivery Conditions: Available in various delivery conditions, including AR, N, TMCP, and TMCP+T, to meet the specific needs of your project.

- Customized Sizes: We provide a wide range of thicknesses, widths, and lengths for both plates and coils to fit your exact specifications.

Applications of Our Bridge Steel Plate & Coil

- Railway Bridges: Designed to withstand high load stresses and provide long-lasting structural integrity for railway tracks and supports.

- Highway Bridges: Used in the construction of roadbeds, supports, and decks that must endure heavy traffic and environmental exposure.

- Bridge Components: Ideal for creating key structural elements like beams, girders, and supports.

Why Choose Our Bridge Steel Plate & Coil?

- Customization: We offer customized sizes and specific steel grades tailored to meet the unique demands of your project.

- High Quality: Our products adhere to strict international standards, ensuring exceptional quality and performance.

- Global Delivery: With efficient logistics, we deliver to key markets across Southeast Asia, Middle East, Africa, Europe, America, and India.

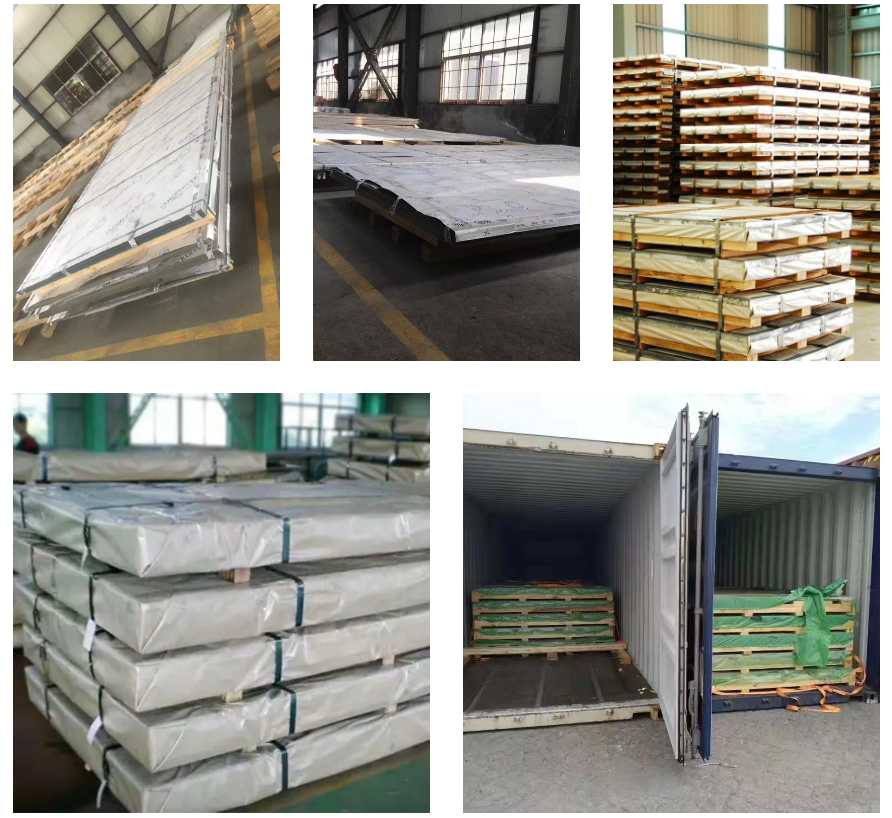

Packaging & Shipping for Bridge Steel Plate & Coil

We understand that the safe and secure delivery of your Bridge Steel Plates and Bridge Steel Coils is crucial. To ensure your products arrive in perfect condition, we use durable and industry-standard packaging methods that protect them during transport.

- Packaging Options:

- Steel plates are carefully wrapped and packed with protective materials to avoid damage during handling.

- Steel coils are securely strapped and wrapped in heavy-duty plastic or corrosion-resistant material to ensure they are protected from environmental factors during transit.

- Packaging Features:

- Waterproof Wrapping: To protect against moisture and corrosion.

- Reinforced Pallets: For easy handling and to prevent deformation.

- Custom Packaging: Tailored packaging solutions are available for specific needs, ensuring optimal protection.

CJM offers fast and efficient shipping to major international markets, and work with trusted logistics partners to guarantee timely delivery and minimize any risk of delay. Our dedicated support team is available to answer any shipping-related inquiries.

Shipping time and cost depend on your location and the order volume. Please contact us for detailed quotes and estimated delivery times for your specific project.

Ready to Start Your Project?

Contact us today for more information on our Bridge Steel Plate and Bridge Steel Coil solutions. We offer competitive pricing and tailored support to meet your project’s specific requirements.

Q: What is your company’s main products/services?

A: We are a professional manufacturer for Carbon Steel, Alloy Steel and Profile products. We have the experience of steel business for more than 10 years and our products are exported to Mid East,South America,Southeast Asia,Africa,South and East Asia etc.

Q: Can I go to your factory for a visit?

A: Of course, we welcome customers from all over the world to visit our factory.

Q: What are your terms of payment?

A: 30% T/T deposite and 70% balance before shipment.

Q: What is your delivery time?

A: For stocks,we could transport the goods to loading port within 7 days after we received the deposit; For production,it usually takes about 15-30 days after receiving the deposit.

Q: Do you provide samples? Are they free or paid?

A: Samples are available for free,but the courier freight will be covered by customer account.

Q: Do you accept the third party inspection?

A:Yes, we fully accept third-party inspections.

Q: Why should I buy from you not from other suppliers?

A: Integrating the superior resources of China’s steel industry, we provide customers with high-quality steel products at preferential prices, and can ensure that the goods are delivered to customers in a timely manner.

Q:How can you guarantee quality?

A: Always a pre-production sample before mass production;Always 100% inspected before shipment

Related products

Monel 400 Plate

- OriginChina

- Delivery Time≥7 days

Monel 400 plate provides exceptional corrosion resistance, strength, and durability, ideal for marine, chemical, and high-temperature applications.

Galvanized C- Channel Steel

- OriginChina

- Delivery Time≥7 days

A36 carbon steel U channel provides excellent strength, weldability, and versatility, making it ideal for construction, fabrication, and structural support applications.

A105 Round Steel Bar

- OriginChina

- Delivery Time≥7 days

A105 round steel bar, offering excellent strength and toughness. Ideal for pressure vessels, flanges, and fittings in industrial applications requiring high performance and durability.

Monel K-500 Plate

- OriginChina

- Delivery Time≥7 days

Monel 500 Plate is a high-strength, corrosion-resistant alloy, ideal for marine and chemical environments, offering excellent fatigue resistance and durability.

loading…

已经是到最后一篇内容了!

CJM Steel Group Ltd.

CJM Steel Group Ltd.