How to Source Quality Steel Plates from China: Tips for Global Buyers

989Learn how to source quality steel plates from China with expert tips on supplier selection, packaging, and pricing. Optimize your sourcing process with CJM.

View detailsSearch the whole station

This page provides in-depth technical information of 4140 steel properties, including chemical composition, mechanical properties, hardness, heat treatment effects, international equivalents, processing guidelines, and welding considerations.

For a broader overview of 4140 steel and its general applications, see our 4140 Steel Overview page.

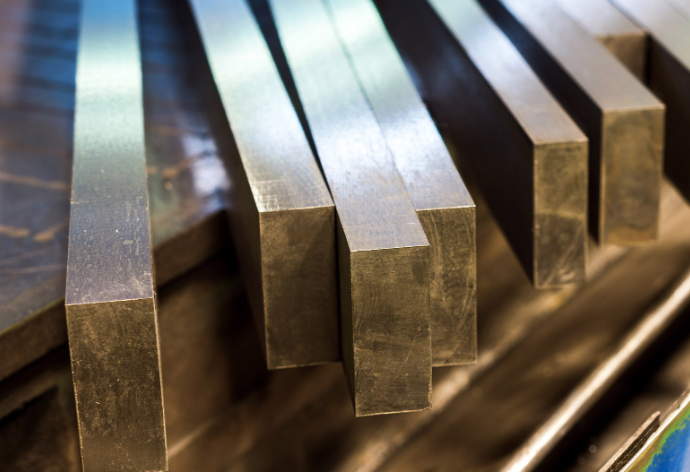

4140 steel is classified as a Cr-Mo low alloy steel. The following table shows typical elemental ranges:

| Element | Typical % Range |

|---|---|

| Carbon (C) | 0.38 – 0.43 |

| Chromium (Cr) | 0.80 – 1.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Manganese (Mn) | 0.75 – 1.00 |

| Silicon (Si) | 0.15 – 0.35 |

| Phosphorus (P) | ≤0.035 |

| Sulfur (S) | ≤0.040 |

Element Functions:

These elemental characteristics are critical for understanding how 4140 steel composition affects heat treatment response and mechanical performance.

4140 steel mechanical properties vary depending on the heat treatment condition. The following table summarizes typical values:

| Heat Treatment | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Toughness (J) | Hardness |

|---|---|---|---|---|---|

| Annealed | 655 – 785 | 415 – 585 | 20 – 25 | 35 – 45 | ~197 HB |

| Normalized | 710 – 850 | 470 – 630 | 18 – 22 | 40 – 50 | ~229 HB |

| Quenched & Tempered | 835 – 1080 | 655 – 900 | 15 – 20 | 35 – 45 | 45 – 50 HRC |

Why Properties Vary:

For many buyers, the 4140 yield strength is the most critical parameter, as it determines load-bearing performance in industrial applications and highlights the importance of understanding 4140 mechanical properties in detail.

When sourcing internationally, it is important to confirm the grade to ensure consistent performance. In particular, verifying the correct 4140 steel equivalent is essential, since different regions may use alternative notations.

| Country / Standard | Equivalent Grade |

|---|---|

| USA | AISI 4140 / SAE 4140 |

| ASTM | A29 / A322 |

| Germany | DIN 42CrMo4 |

| Europe | EN 1.7225 |

| Japan | JIS SCM440 |

| China | GB 42CrMo |

Buyer Considerations:

Proper processing is essential to maintain 4140 steel properties:

Proper welding ensures performance and avoids cracking:

These processing and welding practices help maintain the desired 4140 steel properties, ensuring consistent quality across different manufacturing operations.

When selecting 4140 steel, consider the required mechanical properties, compositions, heat treatment condition, and international standard equivalence to ensure consistent performance. Proper machining and welding procedures are also critical to maintain material integrity and preserve the required 4140 steel properties throughout its service life.

For available 4140 steel plate and bar products, along with detailed specifications for procurement, please visit our 4140 Steel Products page and AISI/SAE 4140 Alloy Steel Bar.

Learn how to source quality steel plates from China with expert tips on supplier selection, packaging, and pricing. Optimize your sourcing process with CJM.

View detailsMonel alloy plate is a high-performance material made from a combination of nickel and copper, offering outstanding resistance to corrosion and high strength.

View detailsCarbon steel rods are strong, durable materials used in construction, manufacturing, and machinery for structural support and components.

View detailsCompare ASTM A36 vs SS400 structural steel. Understand yield strength differences, thickness effects, and whether SS400 can replace A36 in engineering projects.

View details

HelloPlease log in