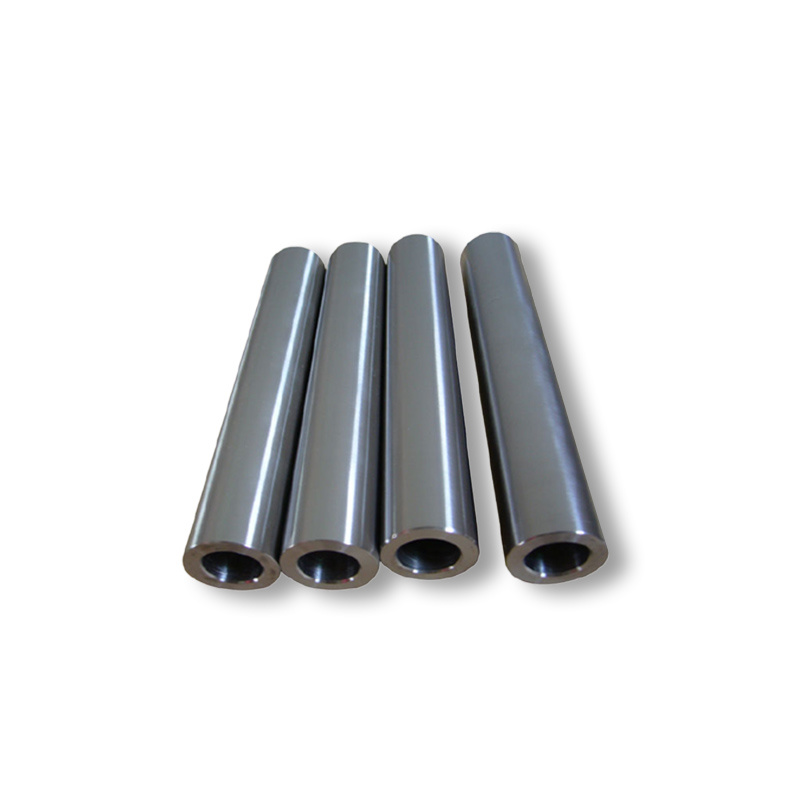

Monel K-500 Pipe

- OriginChina

- Delivery Time≥7 days

- DemandCustomizable

- StandardASTM, AISI, JIS, GB, DIN, EN

- MOQ 1 Ton

Product Description

Stock Display

Inspection and Packaging

FAQ

Related products

Tin-Free Steel (TFS / ECCS) Coils & Sheets

- OriginChina

- Delivery Time≥7 days

CJM supplies tin-free steel (TFS / ECCS) coil and sheet with stable coating quality for packaging. Ready stock, fast delivery. Request a quote today!

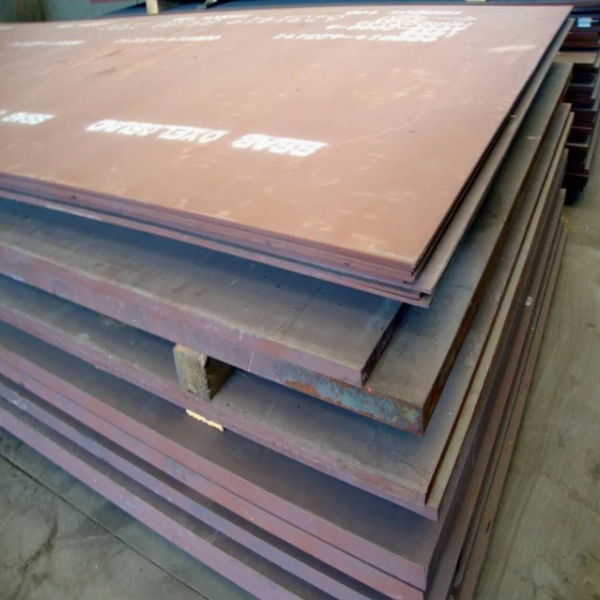

ASTM A709 Bridge Steel Plate Supplier

- OriginChina

- Delivery Time≥7 days

ASTM A709 bridge steel plate in Grade 36, 50, 50W & HPS 70W. Heavy steel plate up to 200mm, rolled & normalized supply for bridge project. Fast global delivery.

API 5L X56 / X60 Pipeline Steel Plate

- OriginChina

- Delivery Time≥7 days

Buy API 5L X56 and X60 pipeline steel plates for oil, gas, and water transport. Certified strength and corrosion resistance for infrastructure projects.

SPA-H / SPA-C Weathering Steel Plate | Durable Weather Resistant Steel Sheets

- OriginChina

- Delivery Time≥7 days

Explore high-quality SPA-H and SPA-C Weathering Steel Plates, engineered for superior atmospheric corrosion resistance. Ideal for containers, bridges, and outdoor structures. Fast delivery worldwide.

loading…

已经是到最后一篇内容了!

MESSAGE:

CJM Steel Group Ltd.

CJM Steel Group Ltd.