Debate sobre las bobinas de acero al carbono

670Las bobinas de acero al carbono son materiales versátiles y duraderos que se utilizan en la industria manufacturera, la construcción y la automoción para diversas aplicaciones.

Ver detallesBuscar en toda la estación

When building or renovating a house, warehouse, or industrial facility, the choice of roofing sheets is crucial. A reliable roof protects the structure from weather exposure while meeting requirements for durability, cost control, and long-term performance.

This guide explains the main roofing sheet types, compares them by material, coating, thickness, service life, and typical applications, and helps buyers understand which type of steel roofing sheet is suitable for different project conditions.

The most widely used roofing sheet types in global construction projects include:

Each type differs in corrosion resistance, appearance, lifespan, and cost, making them suitable for different climates and project budgets.

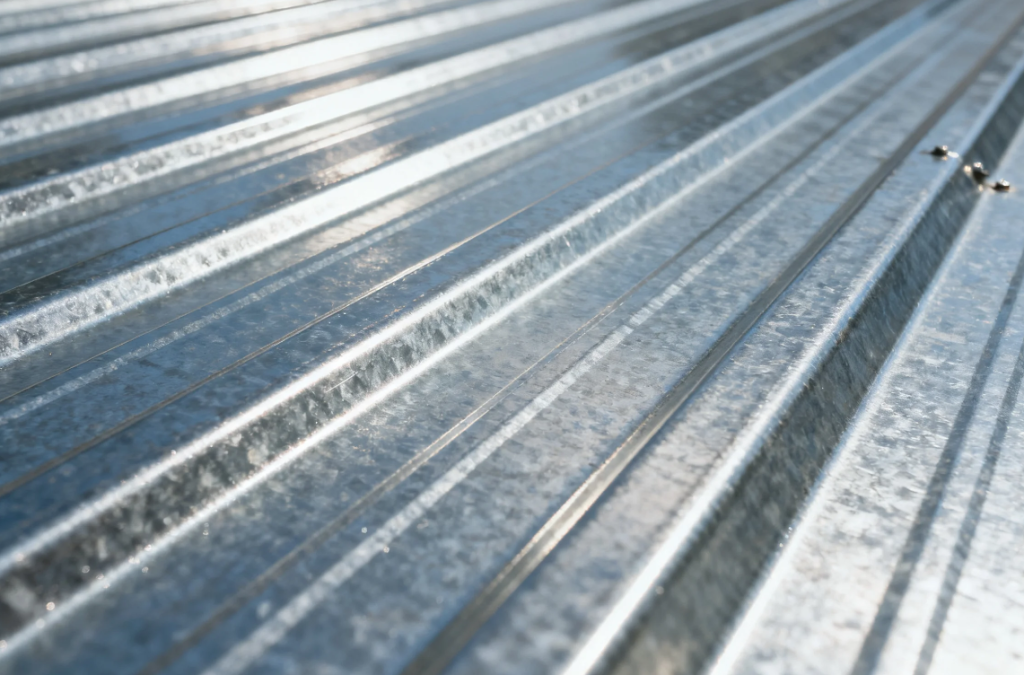

Galvanized (Gi) roofing sheets are produced by coating carbon steel with a layer of zinc to protect against corrosion. Different types of galvanized roofing son classified by zinc coating weight, thickness range, and steel substrate.

Typical applications: warehouses, factories, rural housing, temporary structures, and cost-sensitive projects.

Ventajas:

The table below outlines the most common types of GI roofing sheets used for roofing applications, from light zinc coating to heavy-duty galvanized roofing.

| Galvanized Roofing Type | Low Zinc Coating | Medium Zinc Coating | High Zinc Coating |

| Recubrimiento de zinc | Z40-Z80 | Z100-Z180 | Z275 |

| Gama de espesores | 0,18-0,35 mm | 0.25–0.50 mm | 0.40–0.70 mm |

| Steel Substrate | DX51D / Q195 | DX51D / Q235 | Q235 / SGC340 |

| Spangle Type | Regular Spangle | Ángulo cero | Ángulo cero |

| Typical Service Life* | 5-8 años | 10-15 años | Más de 20 años |

*Service life depends on environmental conditions, roof slope, and maintenance.

For buyers comparing its specifications for procurement, detailed product parameters are available on our galvanized steel roofing sheet product page.

Color coated roofing sheets use galvanized (GI) or galvalume (GL) substrates with a protective paint layer (PE, SMP, or PVDF) applied for enhanced durability and appearance. Different types of coated steel sheets son classified by substrate, coating type, and thickness range. These sheets are widely selected when visual appearance and longer coating life are required.

Typical applications: residential homes, schools, commercial buildings, offices, and urban construction.

Ventajas:

| Especificación | Economía | Estándar | Premium |

| Sustrato | GI, Z100-Z180 | GI, Z180-Z275 | GL, AZ150-AZ185 |

| Tipo de revestimiento | PE | SMP | PVDF |

| Gama de espesores | 0,18-0,35 mm | 0.25–0.50 mm | 0.30–0.60 mm |

| Typical Coating Life* | 8-12 años | 12-18 años | Más de 20 años |

*Service life depends on environmental conditions, roof slope, and maintenance.

Buyers evaluating coated steel sheet options for roofing applications can refer to our PPGI and PPGL Sheets / Coils Product Page for full paint system details.

Corrugated roofing sheets refer to steel sheets formed into wave or trapezoidal profiles. This profile design improves structural strength and water drainage. Different types of corrugated metal panels are classified by profile type, zinc coating, and steel substrate.

Typical applications: farmhouses, sheds, garages, workshops, and light industrial buildings.

Ventajas:

The table below outlines the most common types of corrugated roofing sheets, from light-duty to heavy-duty panels, suitable for various roofing applications.

| Corrugated Roofing Type | Light Duty | Medium Duty | Heavy Duty |

| Profile Type | Wave | Onda / Trapezoidal | Trapezoidal / Custom |

| Recubrimiento de zinc | Z40-Z80 | Z100-Z180 | Z180–Z275 |

| Gama de espesores | 0,18-0,35 mm | 0.25–0.50 mm | 0.40–0.70 mm |

| Steel Substrate | DX51D / Q195 | DX51D / Q235 | Q235 / SGC340 |

| Spangle Type | Regular Spangle | Ángulo cero | Ángulo cero |

| Typical Service Life* | 5-10 años | 10-15 años | 15-20+ años |

*Service life depends on environmental conditions, roof slope, and maintenance.

Galvalume roofing sheets use an aluminum-zinc alloy coating (typically AZ150–AZ185), offering superior corrosion resistance compared to traditional galvanized steel.

Typical applications: Coastal regions, high-humidity areas, industrial zones with aggressive environments.

Ventajas clave:

Galvalume sheets are often selected when lifecycle cost is prioritized over initial material cost.

Tile profile roofing sheets combine the strength of steel with a tile-like appearance. They are usually produced from color coated steel and are popular in residential housing projects.

Typical applications: Villas, townhouses, residential estates.

Key advantages

Al comparar types of steel roofing sheets, consider the following factors:

For cost-driven projects, galvanized or basic corrugated sheets are often sufficient. For residential or long-term projects, color coated or galvalume roofing sheets may provide better overall value.

Las distintas regiones muestran claras preferencias por las chapas de acero para tejados:

Understanding the different roofing sheet types helps builders, contractors, and buyers select the most suitable material for their projects. By comparing galvanized, color coated, corrugated, galvalume, and tile profile steel roofing sheets, it becomes easier to balance performance, lifespan, and cost.

Póngase en contacto con nosotros for technical datasheets, customized specifications, and export support.

Las bobinas de acero al carbono son materiales versátiles y duraderos que se utilizan en la industria manufacturera, la construcción y la automoción para diversas aplicaciones.

Ver detallesExplore impact resistant steel grades for construction, tooling, and extreme environments. Compare A709, 5CrW2MoSiV, AR steel, and more.

Ver detallesCompare common tank plate materials for oil & gas storage tanks. Learn pressure ratings, temperature limits, and code requirements used in real tank projects.

Ver detallesLa chapa de acero al carbono es un material duradero y versátil que se utiliza en la construcción, la fabricación y las aplicaciones industriales como soporte estructural.

Ver detalles

HolaConéctese